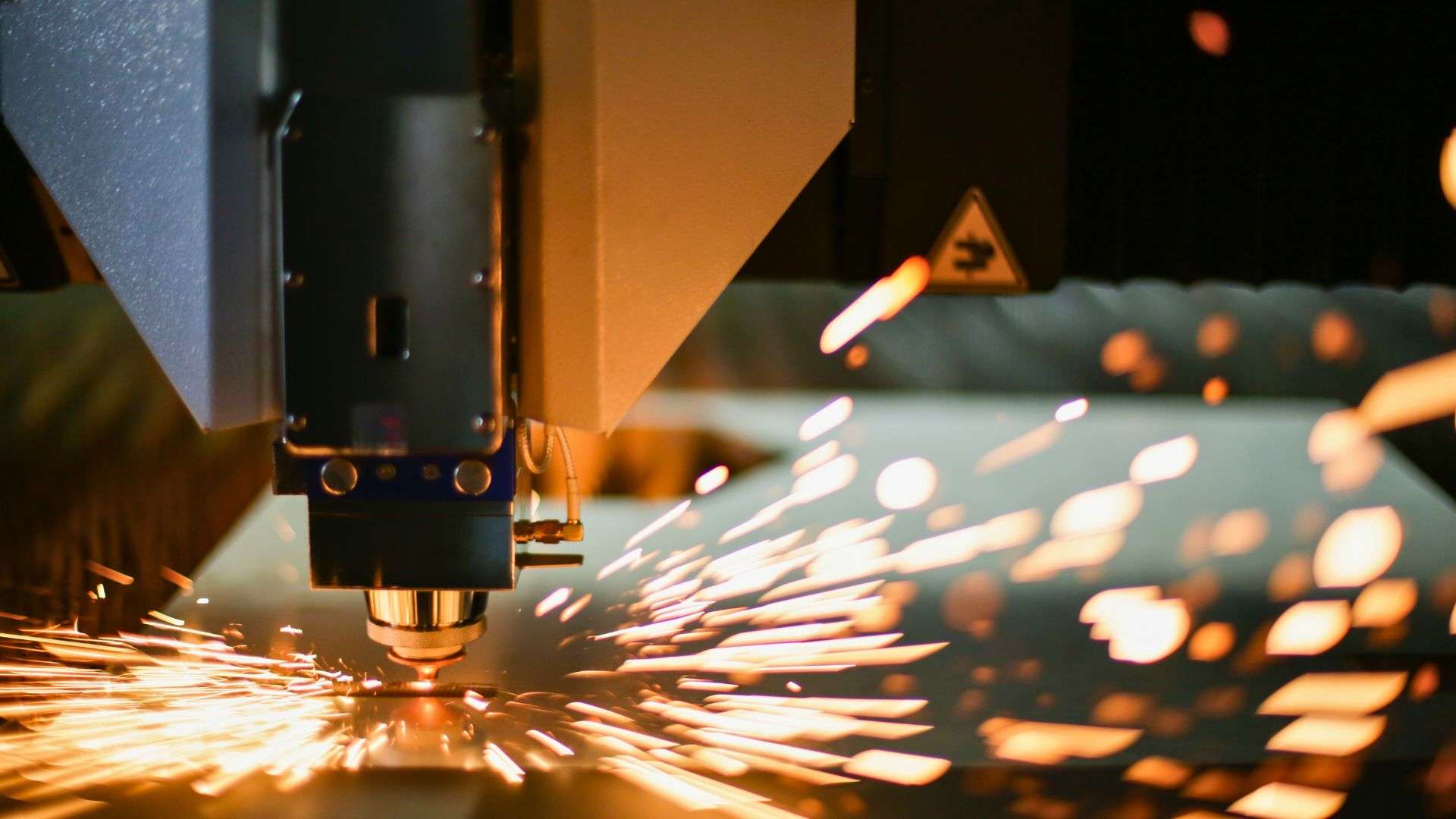

Laser Cutting

Precision metal manufacturing means up to 0.002-inch repeatability fiber lasers, 1200 SPM turret punching, and hybrid nests that cut scrap while sharpening edge quality.

Each job travels with a live digital record that logs tool numbers, offsets, statistical-process checkpoints, and inspection results. Six months down the road you can launch Rev B, or scale from a pilot run to thousands of units, by cloning that very record. With precision metal manufacturing prototype data merging straight into full production, customers typically trim 15–20 percent off total project spend.

Autoloading fiber lasers: power meets finesse

Our fully automated 3 kW fiber lasers focus to a hair-thin spot, delivering crisp cuts and mirror-clean edges shift after shift. An auto-focus head and real-time pierce diagnostics tune dwell on every start, keeping the heat-affected zone tight so edges stay hard and burr free.

- Steel: Up to 1 inch

- Stainless Steel: Up to ¾ inch

- Aluminum: Up to ½ inch

With automated sheet loading and unloading, these lasers run lights-out, driving faster turnaround and consistent quality

Punching: features on the fly

Our CNC turret punches add speed and flexibility:

- Dynamic nibbling and clamp-repositioning hit up to 1,200 strokes per minute

- Automatic tool changes and on-board sensor checks flag wear before it reaches the part

- Forming features like bridge lances and PEM-ready knockouts, all in one cycle

By combining speed, on-the-fly feature forming, and built-in quality control, our turret punching turns raw sheet into near finished parts in a single setup.

Hybrid nests: best of both worlds

Our programmers blend laser and punch paths in the same nest, so every sheet makes a single, efficient trip through the shop. While the laser carves perimeters and larger openings, the punch quietly handles finer internal details as the next sheet stages.

- 10–15 % less material waste by packing parts closer than laser-only nests

- Up to 20 % faster cycles because two processes run in parallel, not back-to-back

One setup, two complementary technologies, faster, leaner, and consistently. That’s the difference of precision metal manufacturing.

Custom laser cutting and CNC punching for

Data center

Retail fixtures

Medical equipment

Scientific

Hospitality

Restaurants

Office furniture

Logistics & warehouses

Electrical enclosures

Railway transport

Lighting

Let's discuss your laser cutting and punch project.

Precision, feature-rich parts, and high material yield seldom appear together, yet our laser-punch hybrid process delivers all three. What you receive is an edge you can weld, bend, coat, and assemble without rework, plus a schedule that saves both calendar days and budget dollars for projects.